Start Innovating!

For Better Products and Machines

Interested in increasing profit margins and strengthening your market position? Value Engineering can help you achieve these goals.

Focus on Price and Performance

Value Engineering is a product development tool focussed on improving the price-performance ratio of products, machines, or equipment. (the term “product” in this text refers to products, machines, or equipment).

Every product is purchased with a specific purpose in mind. The product is required to fulfil a certain function, with decoration or ease of life solutions also being considered “functions”. A product’s ability to perform a certain function can also be used to gauge a product’s performance. As a manufacturer, it is interesting to monitor and develop the performance of your product, as it is the product’s performance that creates added value for your customers.

Four Pillars of Value Engineering

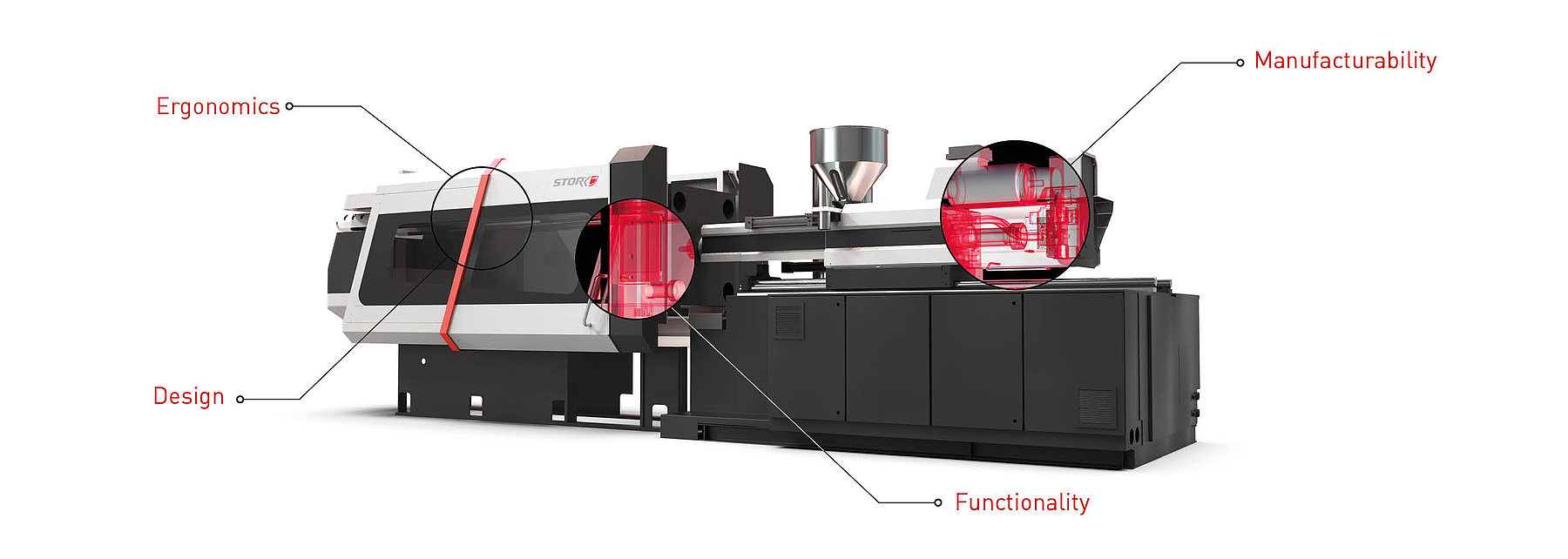

Overall product performance is not only focussed on output (main function) of the product, but also covers aspects such as usability (ergonomics) and design. For the customer, it is important that the desired performance matches a certain price-point. The price that the customer is willing to pay, is seen as the ‘product value’. For a manufacturer it is important to keep the sale price relevant for its customers. The pillar “manufacturability” therefore consists of all costs (time, materials, etc.) required to create the product.

Increase Margins

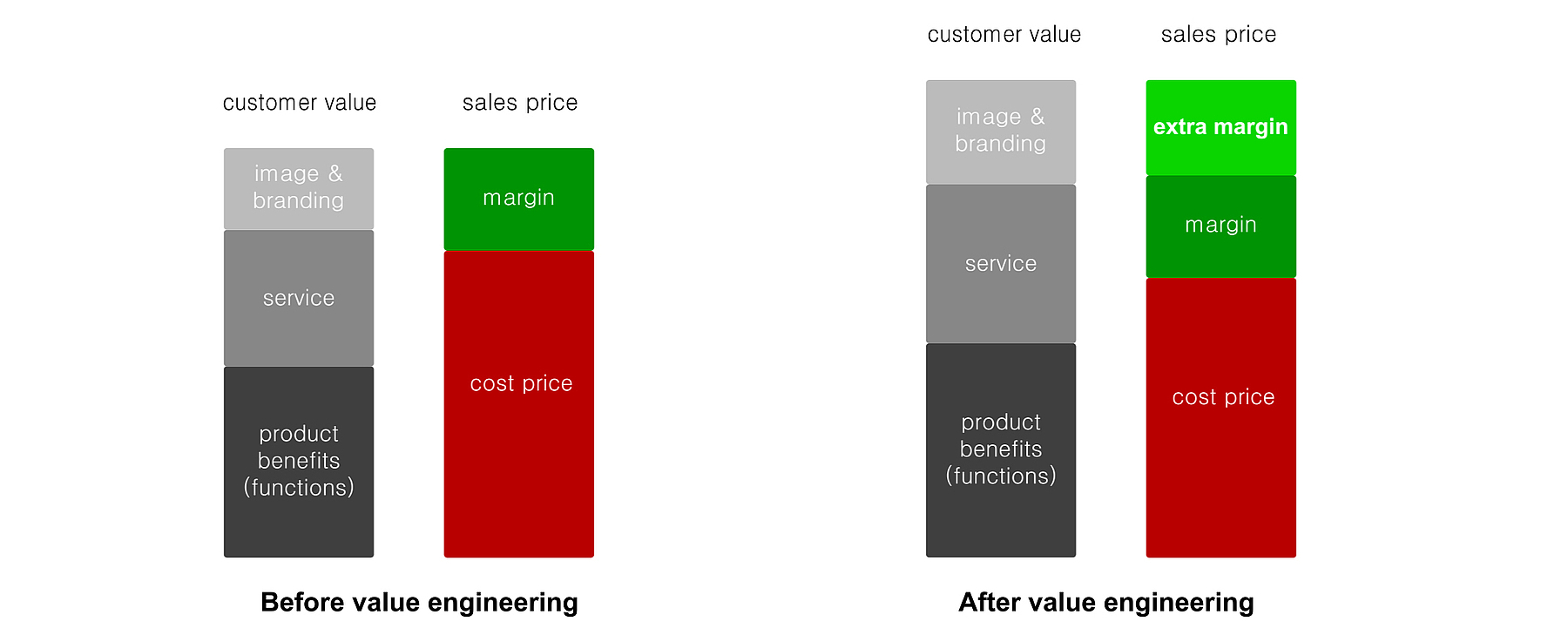

The performance and quality experience of your product benefit your customers, which in turn, are prepared to pay a certain amount for this privilege. However, the profit available, depends heavily on the cost price of the machine. Lower costs therefore result in higher profits.

With Value Engineering it is possible to improve product value whilst maintaining a competitive sales price. In some cases, it is even possible to increase the sales price, providing that benefits for the customer have significantly improved. Apart from adding value, Value Engineering also focusses on reducing the cost price, which also improves profits. The core purpose of Value Engineering is illustrated below.

Impression of value engineering projects

- Cost reduction: 35% reduction in production costs (incl. Optimized assembly);

- Increase in value for the installer: quick installation and maintenance-free;

- Value increase for the user: automatic tap that opens when unwinding (patent 9400203);

- Modular construction of the series with many of the same parts and a timeless design with concealed fasteners.

![[Translate to Englisch:] Value engineering hose pump](/fileadmin/user_upload/Portfolio/Bredel/Bredel_03.jpg)

- Cost reduction: 12% in production costs (materials, production techniques, assembly);

- Increased value for the user: reduction of the Total Cost of Ownership (TCO);

- Increased value for the service technician: faster disassembly of the pump housing, faster hose change and improved visibility of the mounted hose;

- Convincing design: “fit for duty”

![[Translate to Englisch:] value engineering industrial](/fileadmin/user_upload/industrial_cleaner_value_engineering.png)

- 50% lead time reduction between order and delivery by applying a Configure-To-Order strategy;

- Total cost reduction of 33% on engineering hours, labor hours and materials.

- Improved performance of the machine by reducing the energy consumption by 20% by applying more efficient drying techniques;

- Increased value for the user: reduced weight of the cover;

- In addition, overall a more convincing design and improved ergonomics.

- A total cost reduction of 10% (in material costs and assembly hours);

- Frame parts are completely constructed from sheet metal;

- A modular construction: the self-supporting frame is compatible for an optional top platform as well as a laminar flow system;

- Increased value for user and after-sales service: instead of safety gates, fully swing-out doors are used which offer quick and easy access during operational use and maintenance.

- Increased value for user: Improved ergonomics. There is an optimal visibility on the process from all sides;

- Due to its simple and sleek design, the machine has a no-nonsense and hygienic appearance.

Method of Value Engineering

Value Engineering is standardized method (DIN EN 12973 (2002)) and consists of two phases: Analysing and Creating.

The result of the analysis phase provides insight into suspect functions. These are functions that need to be improved and/or have costs reduced.

The creative phase focusses on creating solutions and checking them for feasibility.

Phase 1. Analysis

From Cost per Part to Function Costs

During the analysis phase, sales and marketing provide insight into the relationship between product performance and the price that their customer is willing to pay. R&D is responsible to provide detailed information regarding cost per component, which is used to derive the cost per function. Value Engineering is considered a multi-disciplinary tool and requires equal effort from both commercial as technical departments.

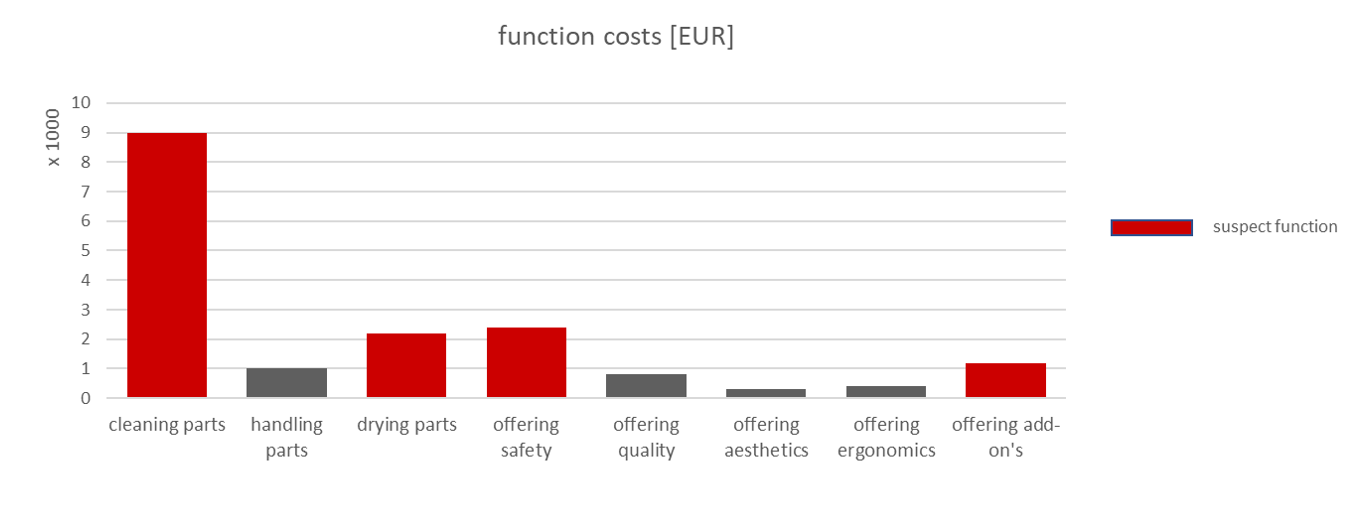

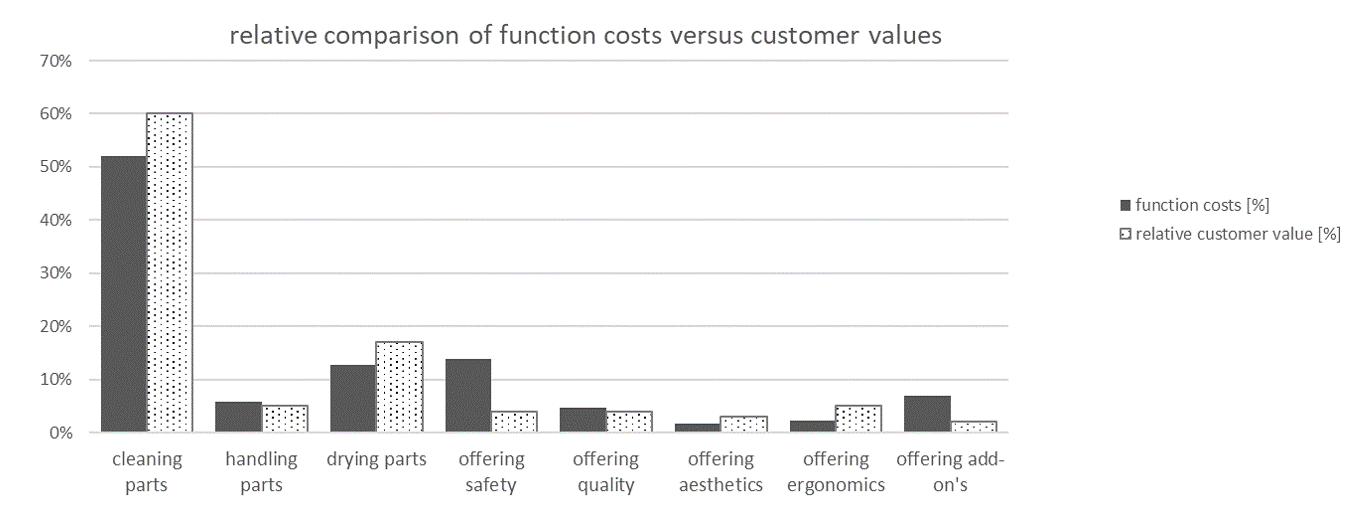

An important part of the analysis involves the use of function-cost-graphs. These graphs provide an overview of the current function costs and allow the identification of the functions with the highest improvement potential.

Thinking About Functions: “Function-Thinking”

As the term “Function-Thinking” might not be familiar for everyone, we have prepared a short explanation:

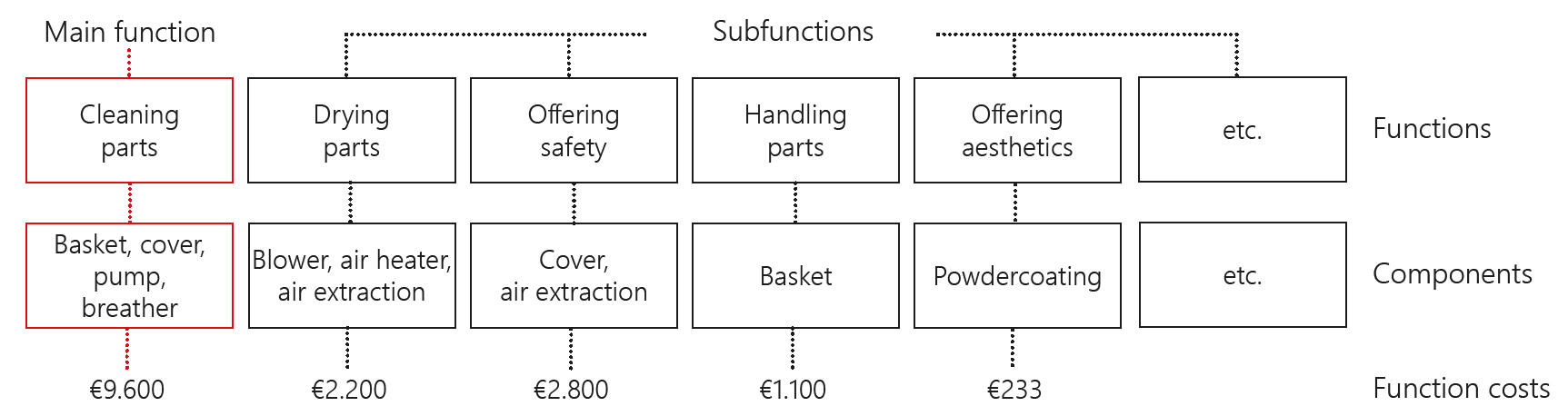

The analysis phase starts with creating an overview of all the functions that the products fulfils. The term “function” refers to something expected of the machine. In case of a crane, for example this can be defined as “lifting a load”. This description is carefully chosen as not to hint towards a possible solution. This allows designers the freedom to research a large variety of solutions, among one which might perform better or be cheaper in production. Once all the functions have been identified, they can be allocated to the components that help fulfil each function. Combining this information with the cost-price of each component, it is possible to determine the cost of each function.

The image above shows the function-tree and function costs of an industrial parts washer. The machine’s main function is to clean parts. This functionality is also the main reason for purchasing the machine. Apart from its main functionality, the machine also provides additional functions that contribute to general operation, safety, or styling. These functions also represent value for which the customer is willing to pay.

Suspect Functions

Once the cost per function have been determined, it is possible to identify suspect or critical functions. Suspect functions are those with relatively high costs, or those who cost more than to be expected based on their role. Value Engineering prioritizes functions with high costs, as these are most likely to offer the highest potential in cost reduction. However, cost is not the only criteria used to evaluate the functions. Quality and performance of the functions are also taken into consideration. Also, a suspect function might be a function that is not yet present but creates added value for the customer.

When evaluating functions, it is important to ask the question: “Is the customer willing to pay this price for this function?” Or “Does the customer need this function?”

“functions are comparable with customer features”. Therefore, we also compare the function costs with the relative value as perceived by the customer. The relative value is based on market insight and requires input from marketing and sales. The graph below shows an example illustrating the difference between function cost and relative value for different functions.

Phase 2. The creative phase

Solution Strategy and Concept Development

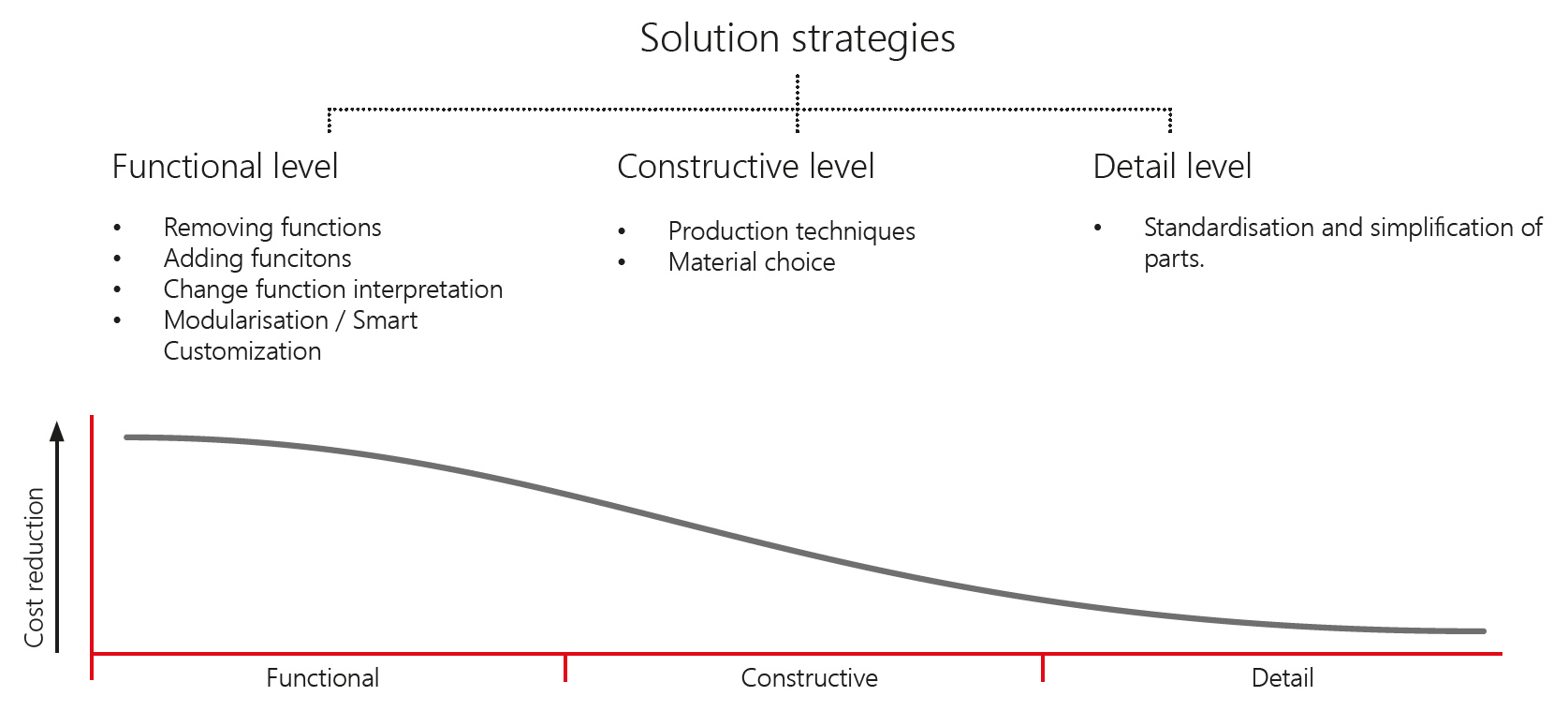

With Value Engineering, cost price reduction or value increase is attempted at three different levels.

Generally, the largest cost reduction can be achieved with functional changes. However, functional changes can also have a much larger impact on implementation than changes on a constructive or detailed level. (e.g. longer development time, higher development budget and possible additional investments for production and assembly).

After selecting the desired solution strategy (level), a start can be made with generating concepts. These concepts are then checked for technical and economic feasibility (separate research project). Implementation of the selected concepts is then done systematically. (separate development project).

Interested in Value Engineering?

Scope

Value Engineering is exceptionally suitable for initiating product innovation and can be used in the following situations:

- Increase customer value and reduce cost price.

- Smart Customization and Engineering-to-Assembly (ETA).

- Situations in which product designs much accommodate a high mix – low volume production (HMLV).

- Situation in which a company wishes to move from Engineering-To-Order (ETO) to Configure-To-Order (CTO) to minimize time spent engineering.

- Creating a strategic innovation roadmap for either short or long term.

- Continuous improvement. Scheduling Value Engineering at regular intervals allows companies to keep finding potential cost savings.

- As a performance indicator through continuous benchmarking of your own product.

Our role

Value Engineering is tailored to your company’s needs.

Below a selection of the possibilities:

- Facilitating Value Engineering projects of your Team.

- Project management (organisation and guidance) for Value Engineering projects.

- Conducting concept studies and engineering.

- Depending on the outcome of the value analysis, we can use the expertise of IDpartners in the field of industrial design, UX design, engineering and market-oriented innovation processes (visit www.idpartners.nl);

- Coaching companies in Value Engineering and during follow-up processes.

We can also train your R&D department in Value Engineering. Based on real-life cases based on your business, we offer a combination of theory and practical application. Interested in what Value Engineering can do for you? Our first consultation is free, during which we discuss possible applications of Value Engineering that might be suitable for you.

Want to know more?

We would be happy to discuss how Value Engineering can work for you. We can be reached by telephone at 0031 53 4301 701. Contact: Jacques Stevens and Arnold Heikoop.

Contact us for our extensive white paper on value engineering.

valueengineering.nl is a website of IDpartners, visit www.idpartners.nl for a complete overview of our services.